Wastewater Treatment General Information

Bio-Pure contains a selected blend of all natural bacterial cultures, enzymes and starting nutrients. These are very effective as a seed or maintenance culture for biodegradation of a wide range of municipal/industrial organic wastes. These include animal, fecal and plant wastes, pulp and paper spent liquids, proteins and fats.

Bio-Pure's cultures, enzymes and nutrients are used to improve biotreatment performance and reduce BOD/COD loads in municipal and industrial water treatment clarifiers, trickling filters, ponds, lagoons, activated sludge systems and aerobic and anaerobic digesters. They are also an ideal blend for quickly destroying grease and fat buildup in drains, sewer lines and lift stations. Periodic use of Bio-Pure will also:

- Reduce overall sludge volume in clarifiers and treatment lagoons through enhanced biodegradation and heightened floc formation with good settling characteristic.

- Provide optimized degradation of organic wastes, including fecal, blood and fats from animal slaughterhouses, meat, poultry and produce processors.

- Metabolize organic sediments in stagnant lagoons or treatment ponds, even under low oxygen conditions.

- Reduce the population of hydrogen sulfide forming bacteria and the odors associated with them, through species competition.

Applications & Solutions

- Organic Overloads - Upsets can be minimized with Bio-Pure bioaugmentation preventing permit excursions or lost productivity.

- Treatment of Specific Compounds - Difficult to treat industrial compounds (such as surfactants) can be targeted with selectively adapted Bio-Pure microorganisms.

- Poor Clarification/Settling - Bio-Pure establishes a high quality biomass and lower effluent BOD/COD that will provide a sludge with better settling characteristics.

- Fats, Oil, & Grease - Compounds of plant, animal, or petro chemical origin can result in serious operational problems as well as permit excursions. Bio-Pure can target these compounds.

- Aeration Basin/Filamentous - Filamentous organisms can be minimized with a targeted bioaugmentation program using Bio-Pure.

- Scum Pits - Bio-Pure cultures can effectively cut grease skimmings traditionally sent to anaerobic digesters or off-site disposal.

- Collection System Maintenance - Bio-Pure cultures can eliminate grease accumulation and H2S in sewer lines and lift stations, drastically reducing maintenance costs.

- Plant Start-Up - Bio-Pure can accelerate and optimize plant start-up.

- Lagoon Treatment - Odor reduction and performance of aerobic and facultative lagoons can be drastically improved using Bio-Pure cultures.

- Overcoming Marginal Operating/Design Conditions - Plants often experience difficulty in maintaining basic requirements for optimum operation. Bio-Pure cultures can help overcome marginal conditions and improve performance.

- Ammonia Removal - Plants can achieve biological nitrification with Bio-Pure culture.

Steps to Implement a Bioaugmentation Program

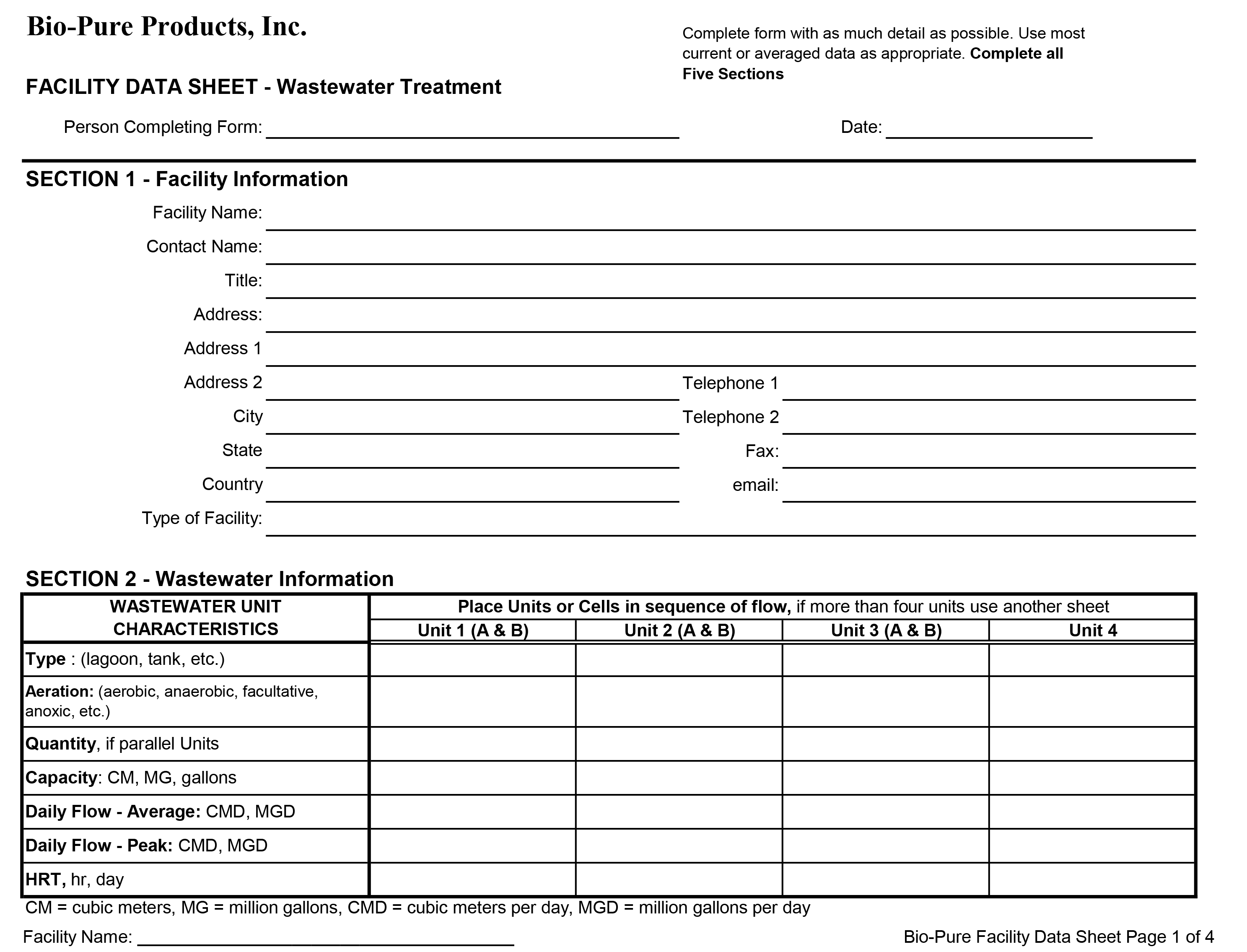

Dosage recommendations for augmenting biological wastewater treatment plants fall into two broad categories: stability related applications and upset recovery or plant start-up. Bio-Pure dosage programs are designed to rapidly achieve results through two phases of culture addition: seeding and maintenance. Dosages are calculated on both organic loading (COD/BOD) and flow rate. During the seeding phase (days 1-7) a high initial inoculum will compensate for the lag phase seen in all bacterial growth. The maintenance phase is designed to sustain the benefits of Bio-Pure selectively adapted cultures once the desired microbial population is established.