BIO-PURE On-Site Organic Waste Treatment is the environmentally safe solution for the biodegradation of a wide range of organic wastes. The success of BIO-PURE Waste Treatment ranges from home septic systems and drains to restaurant grease traps to large multi-million gallon lagoons and complete wastewater treatment plants.

BIO-PURE Waste Treatment is used to improve bio treatment performance and to reduce BOD/COD loads in municipal and industrial water treatment clarifiers, trickling filters, ponds, lagoons, activated sludge systems, with aerobic and anaerobic digesters. In addition, BIO-PURE Waste Treatment is ideal for quickly breaking down grease and fat buildup in drains, sewer lines, and lift stations. Septic systems will also benefit from the application of BIO-PURE Waste Treatment, as it provides the correct strains of bacteria/microbes to your system, breaking down organic mass and improving the function of septic tanks and drain lines.

Multiple Tasks - Single Product

BIO-PURE Waste Treatment has task oriented microbes... not the most microbes, the right microbes. Why buy separate products for each of these tasks when BIO-PURE Waste Treatment does them all? It's 100% natural, environmentally safe, non-caustic, non-acid and safe for humans, plants and animals.

The Viable Choice

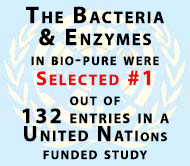

BIO-PURE Waste Treatment works through its unique combination of highly concentrated bacteria and select enzymes.

Enzymes are essentially organic catalysts. Catalysts are defined as substances that will speed up or alter the rate of chemical reactions without the catalyst (enzyme) being altered or used up in the process. This means that since the enzyme isn't actually used up in the digestion process, small amounts go a very long way.

The process by which complex organic compounds, in the presence of water and enzymes, are broken down or transformed into simpler compounds is known as digestion or hydrolysis. Enzymes speed up the union of water with a substance, after which the substance breaks up into fragments. Enzyme action is specifically targeted. Protein splitting enzymes will affect only proteins and not fats or carbohydrates.

BIO-PURE Waste Treatment contains four major enzymes, which enhance the bacteria or microbial activity. The key components are starch- digesting amylases, protein-digesting protease, cellulose-digesting cellulase and fat digesting lipase. As the enzymes begin to breakdown the waste products, the live bacteria in BIO-PURE Waste Treatment go to work. BIO-PURE Waste Treatment contains highly specialized, non-pathogenic strains of bacteria selected for their ability to rapidly digest the nutrient created by the enzyme catalyst. These beneficial microorganisms include both aerobic (with oxygen) and anaerobic (without oxygen) type varieties so that digestion will be assured under a variety of conditions and temperatures. The organisms are harmless, and each batch of BIO-PURE Waste Treatment is certified free of salmonella.

When applied as directed, the cultures will multiply rapidly. The continuous growth, in effect, multiplies the digestive capacity of the system. Since bacteria are complex living organisms, microbial stabilizers, preservatives, enzyme activators, and co-factors have been added as an integral part of the BIO-PURE Waste Treatment formulation. The latest "state of the art" technology has been used in formulating BIO-PURE Waste Treatment.

BIO-PURE Waste Treatment is unique in that each ingredient is environmentally friendly and functional, contributing to a more efficient biodegradation process. Whatever the end use may be, from maintaining on-site sewage disposal systems to hydrolyzing specific waste materials, optimum ingredients are always provided. The most effective, active ingredients available have been used.

Why the need for BIO-PURE Waste Treatment in the home, in industrial and commercial facilities?

Some products contain large amounts of acids, lye or other caustic compounds. These may temporarily burn away some of the clogging material, but their use ultimately causes damage. The harsh chemicals kill bacteria on contact, and prevent the liquefying process that systems depend upon. Furthermore, the chemical can loosen chunks of solids that can get caught in the drainpipes and cause blockage. Caustics also kill beneficial microorganisms and render them useless in the job of digesting the seeping liquid flow from the waste disposal systems. Caustics change soil structure, breaking down the soil into finer particles that pack together, reducing the ability of the systems liquids to seep into the soil. When the bacteria within a system are abused or destroyed, a decrease occurs in the digestion of the organic material that go into the waste disposal system.

The use of BIO-PURE Waste Treatment eliminates the need for chemical treatment and prevents these upsets - safely, efficiently, and economically.

Wastewater - Treatment General Information

Micro Encapsulated Bacterial Cultures, Enzymes and Nutrients

A selected blend of all natural bacterial cultures, enzymes and starting nutrients that are very effective as a seed or maintenance culture for biodegradation of a wide range of municipal/industrial organic wastes, to include animal, fecal and plant wastes, pulp and paper spent liquids, proteins and fats.

BIO-PURE Waste Treatment cultures, enzymes and nutrients are used to improve biotreatment performance and reduce BOD/COD loads in municipal and industrial water treatment clarifiers, trickling filters, ponds, lagoons, activated sludge systems and aerobic and anaerobic digesters. They are also an ideal blend for quickly destroying grease and fat buildup in drains, sewer lines and lift stations. Periodic use of BIO-PURE Waste Treatment will also:

- Reduce overall sludge volume in clarifiers and treatment lagoons through enhanced biodegradation and heightened floc formation with good settling characteristic.

- Provide optimized degradation of organic wastes, including fecal, blood and fats from animal slaughterhouses, meat, poultry and produce processors.

- Metabolize organic sediments in stagnant lagoons or treatment ponds, even under low oxygen conditions.

- Reduce the population of hydrogen sulfide forming bacteria and the odors associated with them, through species competition.

The Right Culture

The one variable in biological wastewater treatment plants that has traditionally been outside operator control is quality of the plant biomass. Bacteria and protozoa in both municipal and industrial biological systems may be negatively impacted by low operating temperatures, toxic chemicals, high substrate loadings, or variable waste streams. Plant start-up and upset recovery require rapid response to maintain the stringent limits imposed by environmental permits. Special environmental problems require environmentally sound biological solutions instead of traditional off-site disposal.

Bioaugmentation

A well-designed and operated biological wastewater treatment plant provides an optimum environment for a microbial population to become acclimated to the incoming wastewater. As long as the basic requirements as described are met, along with a controlled food source, the treatment objectives can usually be met.

Problems arise when the plant becomes overloaded with a particular waste component (e.g., oil & grease) to which the indigenous or native population cannot acclimate. This often results in erratic performance or a plant upset. High organic loadings or periodic shock loads may also contribute to poor plant stability. Finally a deficiency in any of the basic requirements, or periodic toxic or inhibitory conditions, may threaten the health of the microbial population with resulting poor effluent quality.

Bioaugmentation puts the operator in control of the waste treatment plant by allowing a shift in both the diversity and quality of the microbial population.

Selectively adapted strains can target particular waste compounds, improve the treated effluent quality, maintain plant stability, and reduce plant operating costs. Bioaugmentation can also be used for biological remediation of environmental problems ranging from grease deposition in collection systems to H2S formation in collection systems.

Basic Requirements

A biological wastewater treatment plant's goal is to provide an optimum environment for the microbial population. The primary environmental factors include:

- Dissolved Oxygen (DO): Critical to the maintenance of efficient aerobic conditions a minimum DO of 2 mg/L is recommended in all areas of an aeration basin or treatment process.

- Nutrients: Macro nutrients nitrogen and phosphorus must be present in sufficient quantities to support biological growth. The recommended BOD:N:P ratio of 100:5: 1 (based on influent loadings) is the minimum to support good treatment.

- pH: Influent to the biological treatment should be maintained at a pH of 6.8-8.2 at all times during the treatment process. Nitrification is optimized at a pH of 7.6-8.2 and should be closely monitored.

- Temperature: Biological growth occurs at operating temperatures of 45°F [7.2°C] to 140°F [60°C] with optimum growth rate at 70°F [21.1°C] to 90°F [32.2°C].

Applications and Solutions

- Organic Overloads - Upsets can be minimized with BIO-PURE bioaugmentation preventing permit excursions or lost productivity.

- Treatment of Specific Compounds - Difficult to treat industrial compounds (such as surfactants) can be targeted with selectively adapted BIO-PURE microorganisms.

- Poor Clarification/Settleability - BIO-PURE establishes a high quality biomass and lower effluent BOD/COD that will provide a sludge with better settling characteristics.

- Fats, Oil, & Grease - Compounds of plant, animal, or petro chemical origin can result in serious operational problems as well as permit excursions. BIO-PURE can target these compounds.

- Aeration Basin/Filamentous - Filamentous organisms can be minimized with a targeted bioaugmentation program using BIO-PURE.

- Scum Pits - BIO-PURE cultures can effectively cut grease skimmings traditionally sent to anaerobic digesters or off-site disposal.

- Collection System Maintenance - BIO-PURE cultures can eliminate grease accumulation and H2S in sewer lines and lift stations, drastically reducing maintenance costs.

- Plant Start-Up - BIO-PURE can accelerate and optimize plant start-up.

- Lagoon Treatment - Odor reduction and performance of aerobic and facultative lagoons can be drastically improved using BIO-PURE cultures.

- Overcoming Marginal Operating/Design Conditions - Plants often experience difficulty in maintaining basic requirements for optimum operation. BIO-PURE cultures can help overcome marginal conditions and improve performance.

- Ammonia Removal - Plants can achieve biological nitrification with BIO-PURE culture.

Steps to Implement a Bioaugmentation Program

Dosage recommendations for augmenting biological wastewater treatment plants fall into two broad categories: stability related applications and upset recovery or plant start-up. BIO-PURE dosage programs are designed to rapidly achieve results through two phases of culture addition: seeding and maintenance. Dosages are calculated on both organic loading (COD/BOD) and flow rate. During the seeding phase (days 1-7) a high initial inoculum will compensate for the lag phase seen in all bacterial growth. The maintenance phase is designed to sustain the benefits of BIO-PURE selectively adapted cultures once the desired microbial population is established.

Commonly Asked Questions

1. HOW DOES BIO-PURE REMOVE ODORS? Odors are caused by hydrogen sulfide, sulfur, and ammonia. Bio-Pure breaks down & digests organic solids and waste where sulfur- producing bacteria thrive.

2. DOES BIO-PURE REMOVE PIPE SLUDGE? Yes, our secret formulation works on the nutrient sources throughout the complete water column, including the pipe walls. Bio-Pure specifically targets the digestion of organic solids.

3. IS BIO-PURE SAFE? Our bacteria & enzyme strains are indigenous, non-pathogenic, naturally occurring bacteria. They are completely safe and FDA GRAS listed as completely safe for humans, animals and plant life.